Meta Description: A comprehensive guide for electric fireplace wholesalers—resolving 23+ out-of-the-box issues with technical solutions for shipping damage, heating failures, electrical defects, and certification compliance.

Electric fireplaces have become the most popular alternative to traditional fireplaces, particularly in regions like Europe, North America, and the Middle East, where fireplace culture is deeply rooted. Many distributors are seizing this opportunity by sourcing electric fireplaces from Chinese suppliers. However, long-distance shipping often leads to post-unboxing issues. Understanding common problems and their solutions is critical to minimizing risks.

Electric Fireplace Packing Damage

Potential Failure Modes:

- ➢ Corrugated cartons torn or dented due to collisions/compression during transit.Wooden frame fasteners detached.

Solutions:

- ➢ Follow unboxing video documentation procedures.

- ➢ Contact logistics providers and suppliers immediately to negotiate resolutions.

Preventive Measures:

- ➢ Conduct third-party pre-shipment inspections and drop tests.

- ➢ Use reinforced cartons, foam inserts, and corner protectors for bulk orders.

Rust on Metal Parts of Electric Fireplace

Potential Failure Modes:

- ➢ During container shipping, prolonged exposure to moisture or extended transit times may lead to internal rust formation in the electric fireplace.

Preventive Measures:

- ➢ Use custom-made stainless steel components to resist corrosion.

- ➢ Opt for waterproof packaging materials (e.g., moisture-resistant cardboard, plastic film, or waterproof fabric) during transportation.

Solutions:

- ➢ Minor Rust: Remove surface rust with professional rust remover, sandpaper, or steel wool. Apply a rust-resistant primer to the cleaned area.

- ➢ Severe Rust Damage: If critical components (e.g., circuit boards, heating elements) are affected, contact a certified technician for inspection and repair.

Damage or Defects on Electric Fireplace

Potential Failure Modes:

- ➢ The product may develop scratches, cracks, deformities, or other quality issues due to inadequate packaging or vibration during transit.

Preventive Measures:

- ➢ Implement factory pre-shipment video documentation to verify product integrity.

- ➢ For bulk orders:Reinforce packaging with foam padding and edge protectors.Apply surface protective film to the unit.

Resolution Steps:

- ➢ Documentation Protocol: Photograph damaged goods with timestamped evidence for liability assessment.

- ➢ Minor Repairable Damage: Contact our support team for step-by-step repair guidance.

Missing or Mismatched Accessories/Manuals in Electric Fireplace

Potential Failure Modes

- ➢ Post-unboxing discovery of missing or mismatched user manuals/accessories may impact resale operations.

Resolution Process:

- ➢ Inventory Verification: Conduct cross-checking against the agreed inventory checklist upon goods receipt.

- ➢ Replacement Options:

- 1.Submit documented discrepancies for immediate replacement dispatch with tracking number.

- 2.Consolidate missing items with your next order (recommended for cost efficiency).

- 3.Logistics Monitoring: Track shipments via provided tracking number in real-time.

Preventive Protocols:

- ➢ Implement third-party logistics (3L) representative supervision for pre-packaging sampling inspections at factory.

- ➢ Require suppliers to provide digital copies of manuals in advance for interim replacement printing.

Heating System Malfunction in Electric Fireplace

Potential Failure Modes:

- ➢ Failure to activate heating mode

- ➢ Cold air discharge during supposed heating operation

Preventive Protocols:

- ➢ Mandate 100% pre-shipment power-on testing with video documentation from suppliers

- ➢ Require suppliers to provide legally binding 1-year warranty coverage

- ➢ Implement vibration-resistant mounting for heating elements to prevent transport-induced dislodgement

Troubleshooting Procedures:

- ➢ Primary Diagnosis

- 1.Conduct visual/physical inspection of heating element connections

- 2.Perform component re-securement under our remote guidance if dislodgement detected

- ➢ Advanced Intervention

- 1.Engage certified local HVAC technicians for:

- a.Circuit continuity testing

- b.Thermal sensor calibration

- c.Control board diagnostics

Flame Effect Malfunction in Electric Fireplace

Potential Failure Modes:

- ➢ interrupted LED light strips

- ➢ loose reflectors or optical components

Preventive Measures:

- ➢ Install anti-slip locking tabs on LED strips and reflector assemblies

- ➢ Reinforce packaging with shock-resistant foam panels, clearly marking "This Side Up" arrows on exterior cartons

- ➢ Require 24-hour continuous flame demonstration test video prior to container loading

Troubleshooting Workflow:

- 1.Initial Diagnosis

- ✧ Check fastener tightness on LED/optical modules using torque driver

- ✧ Re-secure displaced components following our visual troubleshooting guide

- 2.Technical Support Escalation

- ✧ Initiate live video session with supplier engineers for real-time component diagnostics

- 3.Severe Transport Damage Protocol

- ✧ Engage local certified technicians for:LED continuity circuit verification; Optical path recalibration

- ✧ Negotiate repair cost allocation based on damage assessment report

Abnormal Noise from Electric Fireplace

Potential Causes:

- ➢ Component loosening due to transport vibration

- ➢ Operational noise during initial system self-test sequence

Pre-Shipment Requirements:

- ➢ Demand structural reinforcement of internal assemblies from suppliers

- ➢ Implement vibration-damping packaging materials (e.g., EPE foam inserts)

Troubleshooting Protocol:

- 1.Startup Noise Diagnosis

- ✧ Allow 3-5 minutes for fan lubrication cycle completion

- ✧ Noise typically self-resolving without intervention

- 2.Particulate Contamination

- ✧ Use vacuum cleaner on lowest suction setting to remove debris from:Fan blades; Air intake vents

- 3.Mechanical Loosening

- ✧ Primary Inspection: Verify fastener integrity via our video verification toolkit

- ✧ Professional Support: Schedule on-site technician for:Torque specifications verification ; Resonance frequency adjustment

Voltage/Plug Configuration Mismatch in Electric Fireplace

Root Cause Analysis:

➢ Specification discrepancies arising from incomplete communication during order finalization may result in incompatible voltage/plug standards for local deployment.

Pre-Shipment Verification Protocol:

- ➢ Order Confirmation Stage:

- ✧ Explicitly specify required voltage (e.g., 120V/60Hz) and plug type (e.g., NEMA 5-15) in purchase agreements

- ➢ Pre-Shipment Audit:

- ✧ Deploy third-party logistics (3PL) representative to conduct live video verification of:

- 1.Voltage rating labeling

- 2.Plug specification compliance

Post-Delivery Resolution:

- ➢ Request supplier to expedite certified adapter plugs meeting destination country's electrical standards (IEC/UL certified)

Short Shipment/Mis-shipment Issues

Potential Failure Modes:

- ➢ Quantity/configuration mismatch between physical goods and packing list

- ➢ Potential occurrence of partial omissions or erroneous item inclusion

Reconciliation Process:

- ➢ Discrepancy Documentation:

- 1.Conduct blind count verification within 24hrs of receipt

- 2.Submit timestamped discrepancy reports with:

- a. Unboxing video footage

- b. Annotated packing list cross-reference

- ➢ Replenishment Options:

- 1.Emergency air freight dispatch (recommended for critical shortages)

- 2.Cost-effective consolidation with next scheduled order

Proactive Prevention Measures:

- ✧ Mandate third-party inspection agents to perform:

- a. 100% quantity verification during loading

- b. Random carton content validation against ASN (Advanced Shipping Notice)

- c. Implement ISO-compliant shipping marks containing:

- d. Consignee code

- e. Product SKU

- f. Net/Gross weight (kg)

- g. Color variant

- h. Dimensional data (LxWxH in cm)

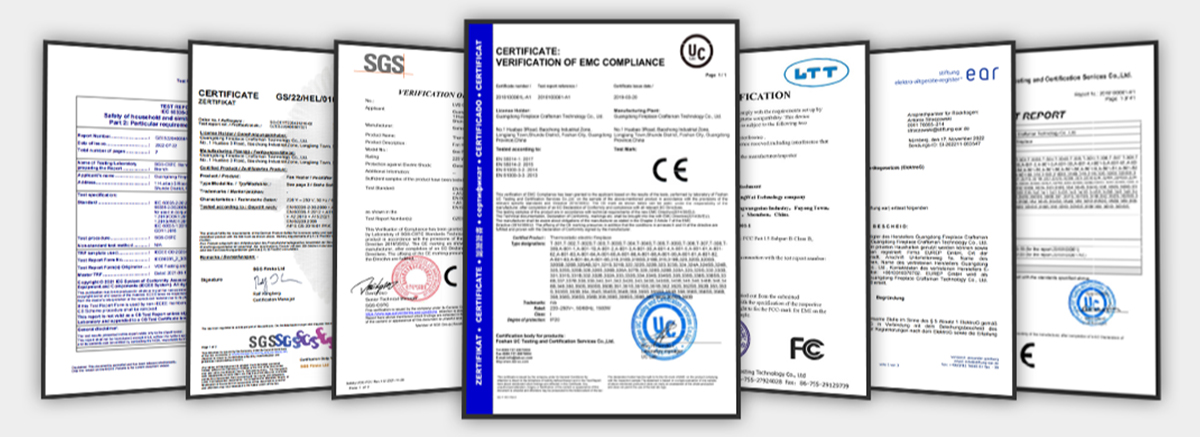

Absence of Electric Fireplace Certifications

Potential Failure Modes:

- Supplier's lack of mandatory market access certifications (e.g., CE/FCC/GS) for target region may result in customs clearance rejection or sales prohibition.

Mitigation Framework:

- 1.Pre Order Compliance Protocol

- ✧ Formally notify suppliers of required certifications in purchase contracts, specifying:

- a. Applicable standard version (e.g., UL 127-2023)

- ✧ Establish legally binding cost-sharing agreement covering:

- a. Testing laboratory fees

- b. Certification body audit charges

- 2.Documentation Safeguards

- ✧ Require pre-shipment submission of:

- a. Notarized certificate copies

- b. TÜV/accredited test reports

- ✧ Maintain digital certification repository with expiration date tracking

Triple-Layer Quality Assurance from Fireplace Craftsman

- While we have mitigated over 95% of potential risks through rigorous pre-shipment controls in production, quality inspection, packaging, and container loading, we provide three-tier protection for absolute confidence:

Transparent Production Monitoring

- ➢ Real-Time Visual Tracking

- a. Schedule video conferences during business hours to remotely observe:

- b. Live production line operations

- c. Quality control procedures

- ➢ Proactive Status Updates (Custom Orders)

- a. Automatically provide video/image documentation at key milestones for client approval

- b. Mold qualification

- c. Prototype testing

- d. Final product sealing

Pre-Shipment Verification

- ➢ For bulk orders:

- We provide HD documentation of laboratory quality inspections and performance testing, while accommodating client-arranged third-party audits of finished products and packaging materials.

- ➢ 2024 client follow-up survey data:

- Pre-shipment verification reduces quality issues by 90% and improves order fulfillment satisfaction rates by 41%.

Extended Warranty Protection

- ➢ New Clients

- a. year comprehensive warranty covering all manufacturing defects (excludes user damage)

- b. Priority video support from our Technical Director within 4 working hours

- ➢ Repeat Clients

- In addition to an 85% cost-efficiency benefit on reorders, we extend warranty coverage by 2 additional years.

Fireplace Craftsman | Your Trusted Electric Fireplace Partner

With over two decades of OEM & ODM specialization in electric fireplaces, having served distributors across 37 countries, we intimately understand the operational challenges faced by B2B partners. This compendium addresses critical pain points to:

● Instill confidence through transparent protocols

● Reduce post-delivery defect rates by 90%+ via preventive engineering

● Streamline issue resolution workflows with 24/7 technical escalation channels

Our data-driven solutions transform cross-border fireplace procurement into a seamless, risk-mitigated experience.

Post time: Mar-10-2025